Product Description:

Product Description

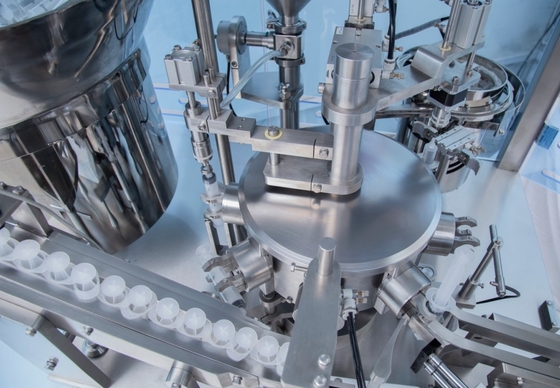

Our company has meticulously designed a product for filling plastic syringes. This equipment is an automatic packaging machine that facilitates aseptic and efficient filling of syringes. The machine has a smooth operation and is user-friendly. It is also equipped with intelligent detection devices that make it highly automated, efficient, and easy to maintain. The technology used in this equipment is at par with current industry standards, making it one of the most advanced equipment available.

The filling of syringes is an essential task in the medical industry, and we understand the need for precision and accuracy in this process. Therefore, with our innovative technology, our product can offer the highest level of accuracy and efficiency in filling the syringes. The device is suitable for a wide range of applications, and it can handle various sizes of syringes, making it ideal for hospitals, clinics, and pharmaceutical companies.

The equipment is easy to install and operate, and it is low maintenance, which makes it cost-effective. Our company's goal is to provide the best product and services to our customers, and this product is a testament to that. With our expertise in the medical equipment industry, we are committed to providing innovative solutions that meet the highest standards of quality and efficiency.

Features:

Product Description

This product is designed for filling and capping of different types of plastic syringes and can be customized according to specific requirements. This machines offers wide applicability making it a popular choice.

It is equipped with superior quality material with the surface being made of SUS 304 stainless steel, and contact components made of SUS 316L stainless steel and medical silicon rubber, thus offering full compliance with GMP specifications.

The ceramic plunger pump offers accurate and quantitative filling of the syringes. It is resistant to acid and alkali corrosion, wears resisting and has high temperature tolerance, and offers a great level of accuracy in filling the syringes.

Conveying and sorting of the capsules is undertaken using the vibrating plate, which is made of SUS 316L stainless steel clean plate, with a surface that has bright treatment and has no clean dead corners. In addition, it adopts internationally well-known electrical components, implementing non-interference modular control, and all synchronous actions are controlled by servo motors, making the machine highly accurate, reliable and easy to operate.

The machine's motor is intelligently controlled by the PLC programming controller with human-computer interaction interface that monitors and displays the status of each station in real-time and provides automated alarm and fault location display, along with prompts for timely fault rectification. The machine offers fully automatic operations, from filling to capping, making it highly convenient to use.

The machine is designed with scientific air-elimination filling technology, which minimizes the air trapped inside the syringe and enhances the overall qualification rate.

The modular design of the machine makes it highly customizable and expandable. It can serve as a standalone machine or easily connected with hoists, assembly machines, rotary rod machines, labeling machines, and other such equipment to form a production line. Additionally, one can choose to use a 100-level laminar flow hood to meet high-demand clean production requirements.

Technical Parameters:

The materials that can be used with this equipment are limited to liquids and ointments. The syringe specifications that can be used with this device range from 0.5ml to 80ml. The filling accuracy of this machine is very precise, ≤±1-2%. This injection dispenser is equipped with one needle for filling purposes. With a production capacity ranging between 1800-2100 pieces per hour, this machine has a total power consumption of 3KW and can be powered on both 380V/220V at 50-60Hz. To operate this device, compressed air is required at the pressure of 0.55-0.75Mpa and 15L/S flow rate. The dimensions of the equipment are L1230×W850×H1800mm and the net weight of this machine is 500KG.

Applications:

Plastic syringe material filling is a common procedure in both the pharmaceutical and veterinary industries. This process involves filling plastic syringes with drugs or medications that are subsequently administered to patients or animals.

Plastic syringes are a popular choice for their durability, versatility, and ease of use. They are ideal for dispensing small and precise amounts of medication, making them suitable for a wide range of pharmaceutical and veterinary applications.

With the help of this procedure, healthcare professionals can ensure that patients and animals receive the correct dosage of medication without any wastage. This makes plastic syringe material filling a cost-effective and efficient solution for drug administration.

Overall, plastic syringe material filling is an important process in the pharmaceutical and veterinary industries that has numerous benefits for both healthcare providers and patients alike.

Customization:

Support and Services:

The Prefilled Syringe Filling Machine is a high-speed, automated system designed to fill and seal prefilled syringes for pharmaceutical and biotech applications. Our technical support team is available to assist with installation, training, and ongoing maintenance to ensure optimal performance and minimal downtime. We also offer a range of services, including system upgrades, spare parts, and troubleshooting. Our team of experts is committed to providing exceptional support and service to help our customers achieve their production goals.

Packing and Shipping:

Product Packaging:

- Dimensions: 120 x 80 x 150 cm

- Weight: 250 kg

- Material: Wooden crate

Shipping:

- Ships from: Manufacturer's facility

- Shipping options: Air freight or sea freight

- Delivery time: 7-15 business days

- Shipping cost: Calculated at checkout

FAQ:

Q: What is the brand name of this prefilled syringe filling machine?

A: The brand name of this machine is HIJ.

Q: What is the model number of this prefilled syringe filling machine?

A: The model number of this machine is HIJ-DZA100.

Q: Where is this prefilled syringe filling machine made?

A: This machine is made in China.

Q: What certification does this prefilled syringe filling machine have?

A: This machine has CE certification.

Q: What is the minimum order quantity for this prefilled syringe filling machine?

A: The minimum order quantity for this machine is 1.

Q: What is the price of this prefilled syringe filling machine?

A: The price of this machine is $30,000.

Q: What are the packaging details for this prefilled syringe filling machine?

A: The packaging details for this machine are seaworthy wooden cases.

Q: What is the delivery time for this prefilled syringe filling machine?

A: The delivery time for this machine depends on the location and order quantity.

Q: What are the payment terms for this prefilled syringe filling machine?

A: The payment terms for this machine are T/T.

Q: What is the supply ability for this prefilled syringe filling machine?

A: The supply ability for this machine is 30 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews