Product Description:

Product Information:

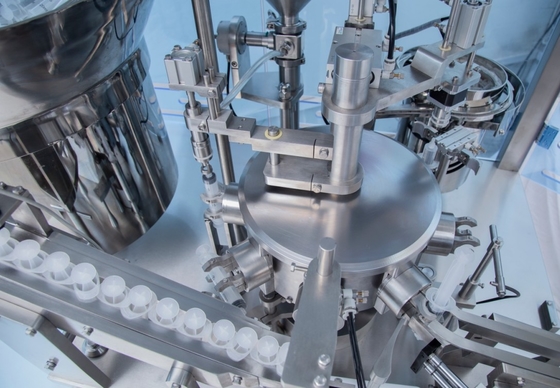

Our company has specially designed a product that is perfect for filling plastic syringes. This product is an automatic packaging equipment that is highly efficient and ensures that the filling of syringes takes place in an aseptic environment.

Equipment Performance:

The equipment is designed to run smoothly and efficiently as well as being quite simple to operate. The machine is equipped with intelligent detection devices that make it highly automated and ensure proper filling of the syringes.

Technology:

The technology used in this equipment is highly advanced and has been developed to meet the current needs of the industry. It is perfect for ensuring quality and efficient filling of plastic syringes and the newest models are highly recommended. The equipment is convenient to maintain and use, helps to improve work efficiency, and is highly valued in the industry.

Conclusion:

Our company has innovatively designed this equipment, ensuring that it meets the highest possible standards. Therefore, if you are looking for the best quality and efficient filling of plastic syringes, this is the right equipment to invest in.

Features:

Product Overview:

This product is specifically designed for filling and capping various types of plastic syringes. Additionally, we are able to customize this product to meet any special requirements that our customers may have.

Product Features:

The surface of this product is constructed from SUS 304 stainless steel, and the contact parts are constructed from SUS 316L stainless steel and medical silicone rubber. This ensures that our product is fully compliant with GMP specifications. Our ceramic plunger pump is acid and alkali resistant, as well as wear-resistant and able to withstand high temperatures. This results in high filling accuracy and a long product lifespan.

The vibrating plate is used for conveying and sorting of the cover, and it is constructed using a SUS 316L stainless steel clean plate. It also undergoes bright surface treatment and has no clean dead corners. By utilizing internationally well-known electrical components, we are able to implement non-interference modular control. All synchronous actions are then regulated by servo motors, resulting in a product that is both accurate and reliable with easy operation.

Operational Control:

The motor operation is controlled by our PLC programming controller, and the human-computer interaction interface monitors and displays the working status of each station in real time.

The entire production process is fully automated, including the filling, capping, and sealing of the syringes. Our unique method of filling the syringe head eliminates any trapped air, optimizing the product quality. The modular design not only makes for easy location and expansion, but also allows this product to be used as a standalone machine or to be connected to other equipment such as a hoist, assembly machine, rotary rod machine, labeling machine, etc., thus forming a complete production line.

Optional Add-Ons:

To meet the demand for high cleanliness production, we also offer an optional 100-level laminar flow hood that can be added to the product.

Technical Parameters:

Product Specifications

This filling machine is designed to work with liquid and ointment materials. It is compatible with syringe specifications ranging from 0.5 ml to 80 ml. With a filling accuracy of ≤±1-2% and one injection needle, this equipment has a production capacity of 1800-2100 p/h.

The machine requires a total power of 3KW and is available in voltage options of 380V/220V, 50-60Hz. The equipment operates on compressed air at a pressure range of 0.55-0.75MPa and requires 15L/s. The machine dimensions are L1230×W850×H1800mm and it has an equipment weight of 500KG.

Applications:

Plastic syringe material filling is a crucial process in both the pharmaceutical and veterinary industries. With its versatility and reliability, it has become a popular choice for practitioners.

Given the importance of accurate and sterile filling, it is essential to use the right equipment and techniques. Many companies offer specialized services for plastic syringe material filling, providing high-quality solutions for various applications.

Whether it is for drug delivery or animal healthcare, plastic syringe material filling ensures the optimal delivery of the required dosage. This not only enhances the effectiveness of the treatment but also minimizes wastage and reduces costs.

Overall, plastic syringe material filling is an indispensable aspect of the modern healthcare industry. As technology continues to advance, we can expect this process to become even more efficient and streamlined.

Customization:

The HIJ Syringe Filling Automation comes equipped with a PLC control system that ensures efficient and precise pre-filled syringe mechanism. It has a weight of 500kg and requires a power supply of 220V/380V 50Hz, consuming 3Kw of power.

Support and Services:

The Prefilled Syringe Filling Machine is a high-speed, fully automated system designed for the filling and sealing of prefilled syringes. The machine is equipped with advanced technologies, including a servo-driven pump system, automatic syringe handling, and a vision system for accurate positioning and filling of the syringes.

The machine is capable of filling a wide range of viscosities and is designed to handle both aqueous and oil-based products. The filling accuracy is ensured through the use of a peristaltic pump system, which provides consistent filling volumes and minimizes product waste.

Our technical support and services team is dedicated to ensuring that your machine is always running at peak performance. We offer a range of services, including installation, training, and maintenance. Our team of experienced technicians is available 24/7 to provide remote technical support and troubleshooting. In addition, we offer on-site service and repairs to minimize downtime and ensure that your production line is always running smoothly.

We also offer a range of spare parts and accessories to keep your machine running efficiently. Our team can provide guidance on the correct spare parts and accessories to use, as well as assist with ordering and installation.

Packing and Shipping:

Product Name: Prefilled Syringe Filling Machine

Description: This machine is designed to automatically fill and seal prefilled syringes with liquid or semi-solid products.

Features:

- Can fill and seal up to 120 syringes per minute

- Easy to operate and maintain

- Accurate and consistent filling

- Compatible with various syringe sizes and types

Package Includes:

- Prefilled Syringe Filling Machine

- Instruction manual

- Tool kit for maintenance

Shipping:

- Ships within 2-3 business days

- Shipping cost varies depending on destination

- Tracking number will be provided

FAQ:

Q1: What is the Brand Name of the Prefilled Syringe Filling Machine?

A1: The Brand Name of the Prefilled Syringe Filling Machine is HIJ.

Q2: What is the Model Number of the Prefilled Syringe Filling Machine?

A2: The Model Number of the Prefilled Syringe Filling Machine is HIJ-DZA100.

Q3: Where is the Prefilled Syringe Filling Machine manufactured?

A3: The Prefilled Syringe Filling Machine is manufactured in China.

Q4: Does the Prefilled Syringe Filling Machine have any certifications?

A4: Yes, the Prefilled Syringe Filling Machine has CE certification.

Q5: What is the minimum order quantity of the Prefilled Syringe Filling Machine and its price?

A5: The minimum order quantity of the Prefilled Syringe Filling Machine is 1 and its price is $30,000.

Q6: How is the Prefilled Syringe Filling Machine packaged and delivered?

A6: The Prefilled Syringe Filling Machine is packaged in seaworthy wooden cases and its delivery time depends on your location. The payment terms are by T/T and the supply ability is 30 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews